eCycle is working diligently to create 21st century personal transportation that provides high performance and owner satisfaction that is both clean and affordable. This vehicle is the eCycle

electric motorcycle.

The motorcycle is attractive, affordable, and environmentally friendly. It is small and light, but has performance that is comparable to vehicles that are both larger and more expensive. Designed from the ground up, the vehicle and its components were created to be innovative, efficient, and inexpensive. There is no other motorcycle that is as advanced as the

eCycle.

Chassis

The eCycle chassis presented an excellent opportunity to eliminate many typical design constraints such as the exhaust pipes, engine, radiator, and fuel tank. All other motorcycle chassis are designed around these items. The chassis is specifically suited to an electric propulsion system. It is made of steel and aluminum to minimize weight and provide heat sinking for the battery pack and electronic components. The battery pack is the size and weight of a typical motorcycle engine and is located low and forward in the chassis to provide exceptional handling. The electric motor and driveline is engineered to function as a racing car driveline functions, carrying loads and integrating as many functions as possible in the fewest number of components.

| Front Suspension: | 1.89 In. (48MM) Inverted Fork |

| 7.5 In. (190 MM) Travel | |

| Rear Suspension: | Penske Racing Coil-Over Mono-Shock, |

| Ride-Height Adjuster 5 In. (127 MM) Travel | |

| Front Brake: | Single Four-Piston Caliper |

| 11.75 In. (298 MM) Disc | |

| Rear Brake: | Single One-Piston Floating Rotor |

| 8.5 In. (215.9 MM) Disc | |

| Front Wheel: | Marchesini 17 x 2.75 In. Aluminum |

| Rear Wheel: | Marchesini 17 x 2.75 In. Aluminum |

| Front Tire: | MT 75, 110/70-17 |

| Rear Tire: | MT 75, 130/70-17 |

| Rake/Trail: | 24.0 Deg./3.9 In. (98.3 MM) |

| Wheelbase: | 52.0 In. (1321 MM) |

| Seat Height: | 30.0 In. (762 MM) |

| Weight: | 290 Lbs. (132 Kg) |

Frame

The tube frame used to carry the front forks and the battery pack is made of steel and joined by brazing and welding. The frame design was refined using FEA (finite element analysis). Powder-coated for durability, the frame is light, strong and tough.

The tube frame integrates with an aluminum box-section sub-frame that carries the rear suspension and driveline. The two main load-bearing members of the sub-frame assembly also perform other functions vital to the motorcycle - one side doubles as the main heat sink while the other side houses the transmission and picks up the suspension.

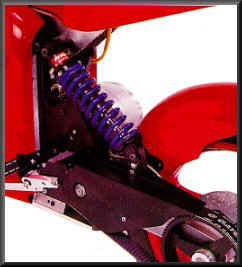

| Suspension

The front suspension is an inverted fork. The rear suspension, pictured to the right, is a single sided swing arm with a built-in caliper and a coil-over mono-shock. |

|

Styling

The bodywork is a combination of parts specially designed or modified to dress up the eCycle. The tank-seat-tail (TST) is rotationally molded low-density polyethylene (LDPE), which is recyclable. The side panels, upper fairing, and rear fender are thermoformed acrylonitrile - butadiene - styrene (ABS.) The front fender is made of composite material.

Batteries

Batteries are a subject in and of themselves. The battery pack is our gas tank and engine as well. The function of the motor is to convert the electrical energy (amps, volts, and watts) into kinetic energy (torque, rpms, and horsepower) as efficiently as possible. The battery is not truly the source of the energy. The outlet you charge from provides the energy, while the battery pack serves as a low resistance energy storage device. The controller and charger manage the energy. The reason the battery pack must have low resistance is to minimize the amount of heat dissipation due to charging and discharging. The energy density of batteries defines how much energy is available in a given unit of mass. In our case, we are presently using sealed lead-acid (SLA) batteries. The resistance of SLA is low and yields a high power density of more than 300 watts/Kg.

Motor

|

The permanent magnet motor is a new design that comprises features which make it more suitable for vehicles (in particular motorcycles) than other types of motors. First, it is very short in the axial dimension which makes it small and lightweight. Second, it has been designed to use the latest controller technology with the minimum number of parts in order to decrease cost and increase reliability. |

| Third, eCycle is using a combination of a two-speed transmission and high voltage to provide both high torque off the line and high speed capabilities. eCycle has incorporated new and innovative technology into the motor which is enabling in cost and performance. | |

Lights The lights employed for the tail/brake light and turn signals are light emitting diodes (LEDs.) The high flux density type LEDs used are similar to what you see in the spoiler of a sports car. These lights are safer because they illuminate quicker. The LEDs will last much longer then a conventional light bulb, and draw about 1/5 the average current of an incandescent bulb. |

|

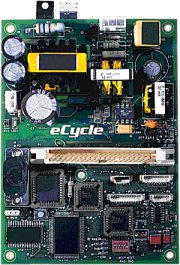

Vehicle Electronics

|

The eCycle has many electronic elements grafted into one comprehensive system. The brain of the control is the newest in technology 100 pin micro-controller. We have developed software which is very fast to perform all the tasks on one computer. Everything from the throttle to the charger, including the instrument panel and safety interlocks are centrally maintained. One feature of the micro-controller is the ability to send pulse-width-modulated signals (PWM.) This PWM signal is sent to an electrically isolated power interface which in turn drives a switch. The switch is called an insulated gate bipolar transistor (IGBT.) The IGBT switches the high voltage and current in proportion to the riderís demand. |

| The battery packís nominal voltage is 144. On board DC to DC converters provide 5V to run the electronics and 13V to run the lights anhorn. The designs for these devices are built into the main control board as part of the integrated control system. | |

Copyright © 2002 eCycle, Incorporated